PVC & CPVC Flanges [Van Stone]

PVC & CPVC Flanges

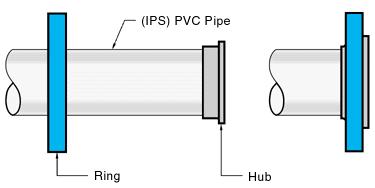

Van Stone Style Flange—Socket (Two-Piece)

Van Stone Style Flange—Socket (Two-Piece)

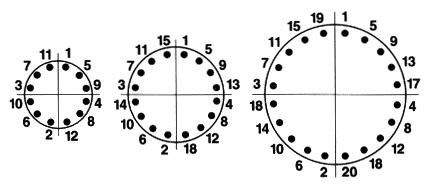

Sizes 10" through 24" Diameter Drilling Pattern…Class 150

United Equipment & Fabriactors' unique back-up rings are computer designed with a configuration engineered for maximum performance. The combination of hubs and back-up flange rings represent the most innovative two piece (Van Stone) style flange available today.

|

|||||||

|---|---|---|---|---|---|---|---|

| Size | PSI at 73° | O.D. | Bolt Circle Dia. | No. of Bolt Holes | Bolt Size | Min. Bolt Lengths | Approx. Wt. (Lbs.) |

| 10 | 150 | 16-1/16 | 14-1/4 | 12 | 7/8 | 5 | 12.36 |

| 12 | 150 | 19 | 17 | 12 | 7/8 | 5 | 17.12 |

| 14 | 150 | 21 | 18-7/8 | 12 | 1 | 5-1/2 | 26.80 |

| 16 | 150 | 23-9/16 | 21-1/4 | 16 | 1 | 6-1/2 | 37.50 |

Sizes 10", 12", 14" and 16" flanges are Van Stone style which means they have a free-floating ring that enables the bolt holes to be aligned after the flange has been assembled to the pipe, greatly simplifying installation. The Van Stone rings are manufactured from a glass reinforced PVC composite called FIBERLOC (FIBERLOC is a material of BF Goodrich.). This material increases strength and durability, and provides a rigid mating surface that is less susceptible to stresses typically encountered during field installation. These flanges are designed and manufactured to Class 150 Specifications, per ANSI-B16.5 requirements. The sealing surface is of a modified flat face design, in which raised ribs uniformly grip the gasket material during compression, ensuring a leak proof seal. We recommend the use of a full face, 1/8" thick, flat Neoprene gasket.

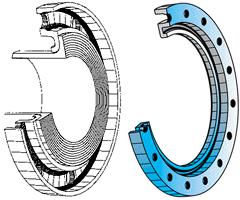

Sizes 18", 20" and 24" hubs are formed by United Equipment from durable PVC pipe as a single piece construction, containing no cementing or hand welding. These 18", 20" and 24" hubs include a convoluted style cast ductile iron (ASTM536) back-up ring. Back-up rings include a baked-on polyester resin coating. Bolt circle is ANSI-B16.5 Class 150. Our unique convoluted style back-up ring design eliminates the need for bolt retightening because of their capability to store elastic energy somewhat like a “Belleville Washer”…the flange preloads the bolts as they are tightened (see torque recommendation and tightening pattern).

10" and 12" flanges are also available in Spigot ends, and are also available in CPVC.

| Size | PSI at 73° | O.D. | Bolt Circle Dia. | No. of Bolt Holes | Bolt Size | Min. Bolt Lengths | Weight (Lbs.) |

|---|---|---|---|---|---|---|---|

| 18 | 75 | 25 | 22-3/4 | 16 | 1-1/4 | 6-1/2 | 60 |

| 20 | 50 | 27-1/2 | 25 | 20 | 1-1/4 | 6-1/2 | 83 |

| 24 | 50 | 32 | 29-1/2 | 20 | 1-3/8 | 7 | 98 |

INSTALLATION of FLANGES

1.0 Flanges 18" through 24" are fabricated from pipe, not molded. Flanges 16" and under are molded.

2.0 Alignment is critical, as these flanges are not designed to pull together under stress or pull the weight of the piping system together.

3.0 Recommended 1/8" thick Neoprene gasket.

4.0 The faces of United Equipment flanges are raised phonographic grooved finished so that when the bolts are tightened, the faces will be pulled together creating a positive seal on the gasket.

INSTALLATION TIPS

5.0 Once a flange is joined to pipe, the method for joining two flanges together is as follows:

5.1 Make sure that all the bolt holes of the matching flanges match up. It is not necessary to twist the flange and pipe to achieve this.

5.2 Insert all bolts with full size flat washers under heads and nuts.

5.3 Make sure that the faces of the mating flanges are not separated prior to bolting down the flanges.

5.4 The bolts on the plastic flanges should be tightened by hand until snug then by pulling down the nut diametrically opposite each other using a torque wrench. Complete tightening should be accomplished in stages and the final torque values in the following table should be followed for the various sizes of flanges. Uniform stress across the flange will eliminate leaky gaskets.

5.5 “CAUTION”, THESE ARE PLASTIC FLANGES, NOT STEEL…alignment must be achieved prior to tightening bolting. Attempting to draw together or fix misalignment by tightening bolting may result in cracking of the flange hub. Unnecessary overtightening will damage the flange.

5.6 TORQUE TABLE

| Flange Size (inches) | Maximum Recommended Torque (FT. LBS)* |

| 10" | 64-75 FT/LBS |

| 12" | 95 FT/LBS |

| 14-24" | 110 FT/LBS |

* THESE RECOMMENDATIONS ARE BASED ON THE USE OF FLAT FLANGES, TWO STANDARD FLAT WASHERS, STANDARD NUT AND A 1/8" THICK, FULL FACE NEOPRENE GASKET. LUBRICATE HARDWARE WELL, TIGHTEN IN THE PROPER PATTERN AND APPLY TORQUE IN SMALL INCREMENTS.

5.7 If the flange is mated to a rigid and stationary flanged object, or a metal flange, particularly in a buried situation where settling could occur with the plastic pipe, the plastic flange and the fitting or valve must be supported to eliminate potential stressing.

Previous page: Fiberglass Shower / Patio Liners

Next page: Flexible Liners